Case Study: Metal Labels for Scented Candle Glass Packaging

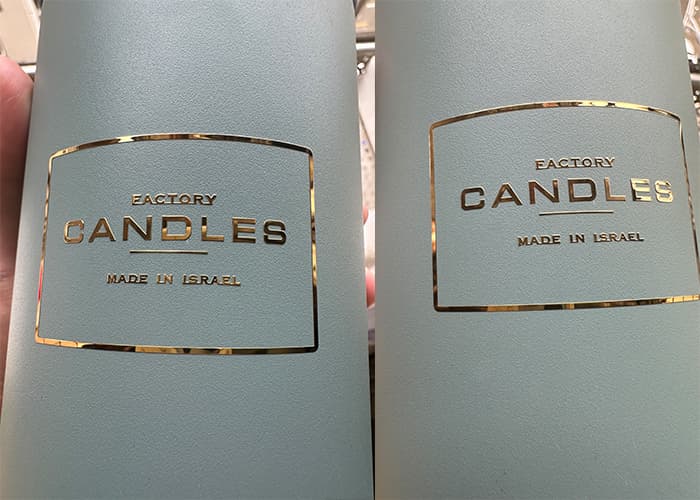

In June 2016, the production manager of an Israeli candle factory reached out to us. They needed a high-end sticker for their various glass candle jars, and our nickel stickers perfectly matched their requirements. The smooth metallic gloss enhances the logo, making it look more luxurious.

They told us, "Your stickers and service quality are far better than most factories out there." Here’s why:

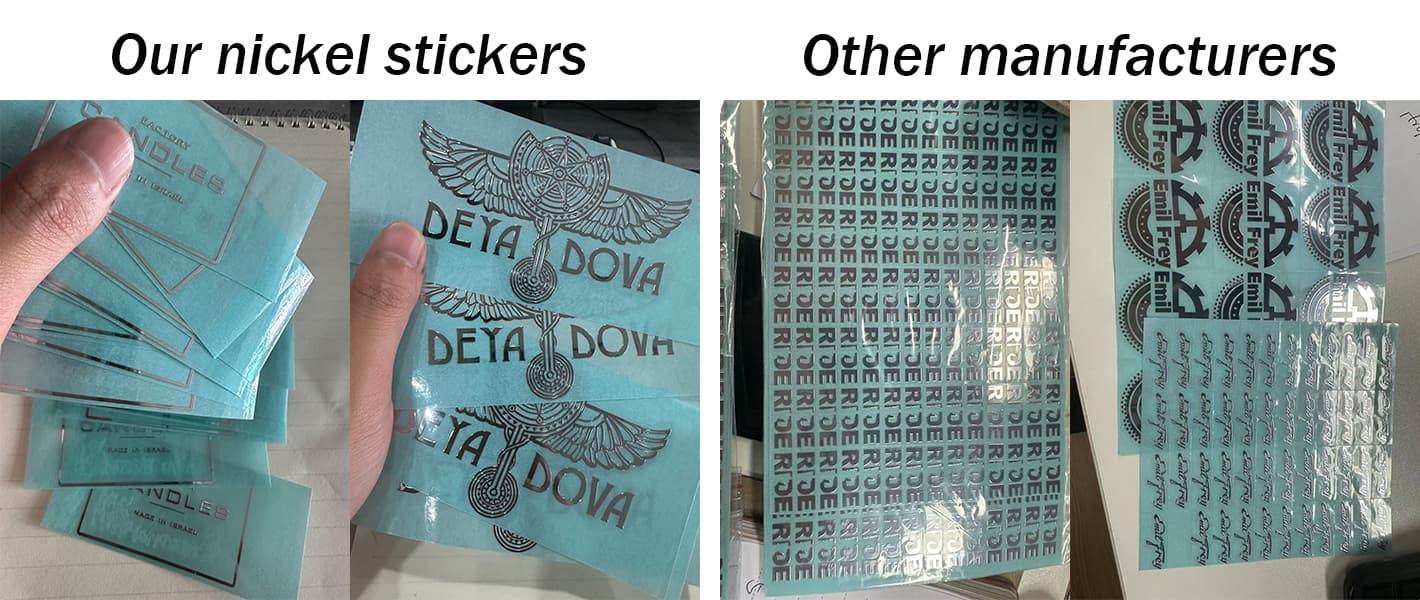

We support individual cutting and packaging for each logo, making them easier to use and store.Most suppliers stack stickers together on a single sheet, which can lead to damage during shipping and storage difficulties.

In terms of quality, we perform multiple electroplating and rinsing processes, ensuring a flawless surface. When customers compare our products with others, they notice our superior attention to detail.

At the beginning of our collaboration, we faced a major challenge. Back then, our technology wasn’t as refined. When the client applied our stickers to their glass candle jars, nearly half of them developed issues by the next day—letters fell off, edges lifted, and many stickers were wasted (see customer feedback photos below).

To solve the problem, we tested repeatedly and made continuous adjustments. After nearly 35 iterations (fine-tuning thickness and adhesive), we succeeded in creating nickel stickers thinner than any on the market—just 0.04mm. After sending replacements, the client tested them immediately and was thrilled with the results. The stickers adhered perfectly to the glass jars, remaining firmly in place even after days.

Ultimately, after the client launched their candles, packaging-related complaints dropped by 95%. The premium nickel stickers even helped attract new customers (see photos of the final product below). We’ve been working together since 2016, and our partnership continues to this day.

Regarding thickness:

0.04mm is achievable for silver nickel stickers (since nickel is naturally silver-white, no additional plating is needed).For other plating colors, we add 0.01-0.02mm for electroplating, but this doesn’t affect performance unless extreme precision is required.

If you need even finer customization, we welcome your inquiries—we love a good challenge! :)